These Malaysian researchers came up with a coconut-based armor, and it actually works

- 708Shares

- Facebook678

- Twitter4

- LinkedIn6

- Email3

- WhatsApp17

Growing up with a Malaysian education, you might have at some point been asked to write a karangan about the coconut tree to the tune of ‘Pokok Seribu Guna‘, or literally the tree of a thousand uses. Apparently every part of the tree can be used for something, if you’re creative enough.

The leaves can be used to wrap ketupat, you can use the trunk to build bridges, and the leaf spine can be collected and turned into a broom. Even the seemingly useless coconut husks and the roots can be used as firewood, and if you include all the recipes we have that include santan and coconut shavings, plus other unconventional uses…

…we may actually come close to a thousand (or more) uses for the coconut tree. And that list just keeps on growing. Recently, researchers from Universiti Putra Malaysia’s Institute of Tropical Forestry and Forest Products (INTROP) found another use: as a bulletproof vest.

That sounds interesting, so we dropped by INTROP and spoke to Dr Mohamad Jawaid, the lead of the research team that came up with it. As it turns out…

By replacing Kevlar with coconut leaf sheath, the cost was slashed almost in half

Typically, bulletproof vests are just normal vests with bulletproof plates in them, and a common bulletproof plate consists of three layers: a ceramic plate, layers of a fabric woven from a synthetic fiber called Kevlar, and a metal alloy plate. When a bullet hits this plate, the ceramic plate breaks on impact, and the Kevlar fibres further slows down the bullet, dissipating the impact.

Kevlar is a pretty pricey fibre, though, with its raw materials alone being said to cost somewhere between five to twenty times the raw materials for fabrics like nylon and polyester. Dr Jawaid had been researching natural fibres, and after comparing fourteen types of natural fibers, his team found that the one best suited for stopping bullets is a relatively useless part of the coconut tree: the leaf sheaths.

Coconut leaf sheaths are an example of a naturally woven fiber, which means that they naturally weave themselves into a fabric-like sheet. Here’s a leaf sheath sample that he showed us, and a sample of Kevlar fabric:

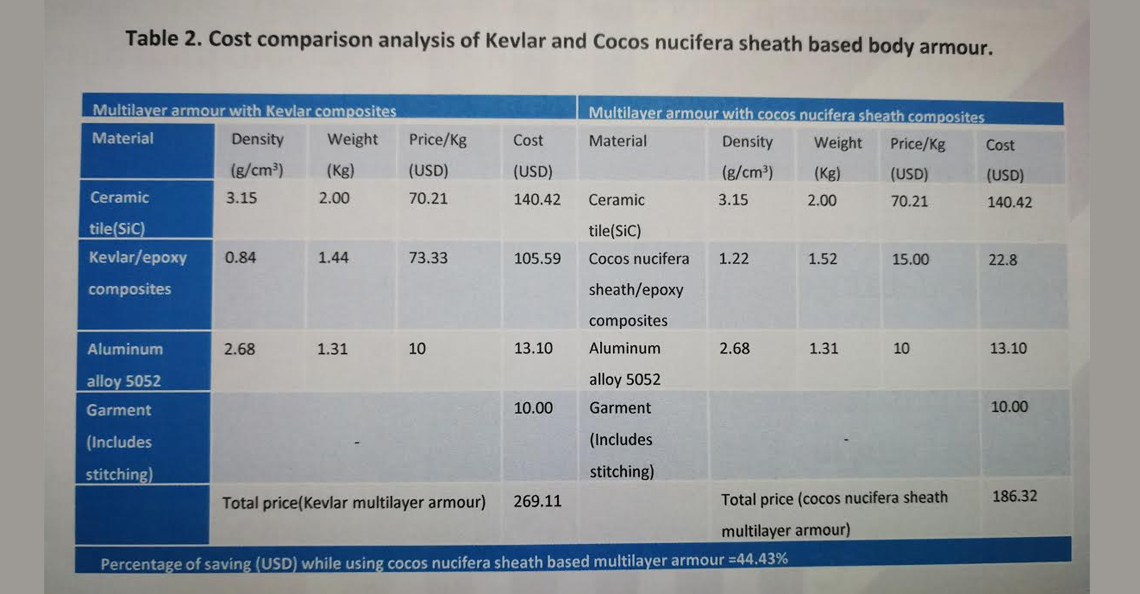

Since they’re already in sheet form, not much processing is necessary to turn them into a ballistic plate: you just need to layer them together, glue the stack with epoxy, and put them between a sheet of ceramic and metal alloy. By replacing Kevlar with coconut leaf sheath, the estimated raw material cost is reduced almost by half, or 44.43% if we’re being picky.

Interestingly, after experimenting with combinations of coconut leaf sheaths and Kevlar as well as coconut leaf sheaths improved with graphene (which are costly as well), but it was found that just plain coconut leaf sheaths do the job better.

“Previously we’ve also done Kevlar and coconut… we’ve also done modifications on the coconut using graphene nanoparticles to improve the property… but we found that the non-graphene one is better.” – Dr Mohamad Jawaid, to Cilisos.

Sure, you might be thinking. It’s cheap, but will people be willing to wear them into battle? Well, we dunno if they’re willing, but you should know that…

Despite being cheaper, coconut leaf sheath in armor is almost as effective as Kevlar

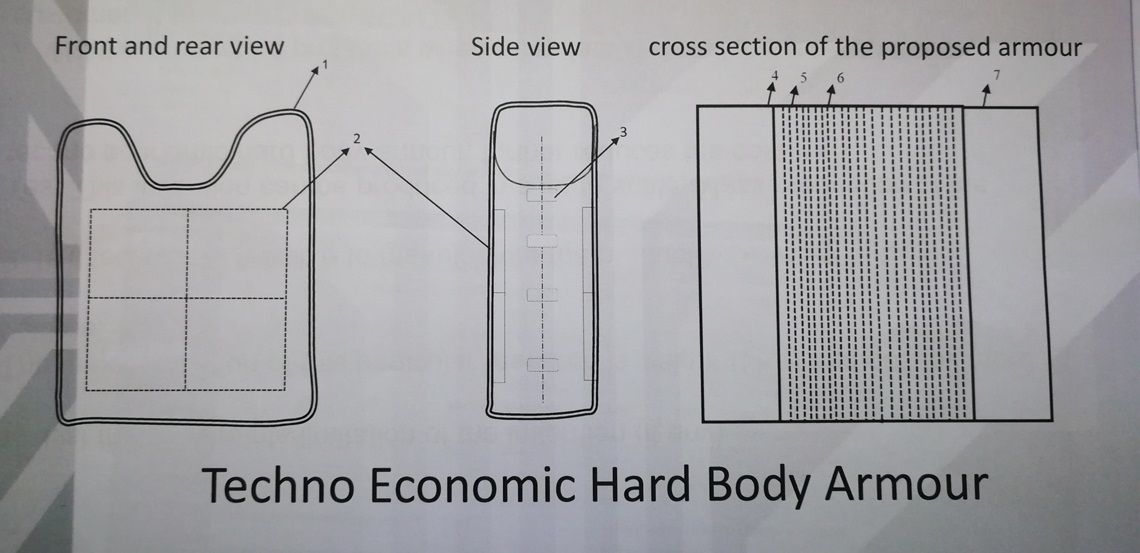

We should really stop calling it coconut armor, as Dr Jawaid’s team came up with a name for the innovation already: the Techno-Economic Hard Body Armor, or TEHBA. And the one in the picture isn’t really the final version; it’s a prototype of sorts, with improvements to the design planned in the future.

Anyways, as we’ve said earlier, bulletproof vests work by dissipating the force by an approaching bullet, which means that it makes a gunshot feel less like a piercing spear and more like a blunt hammer.

Wearing a bulletproof vest will hopefully stop bullets from piercing your skin and damaging the organs underneath, but some damage will still happen. The measure of a good bulletproof vest is how shallow the resulting damage is, and this is measured through something called the backface signature. To do this test, you basically put the bulletproof material in front of a block of clay, then shoot into the material. The depth of the resulting crater is then measured to give you the backface signature.

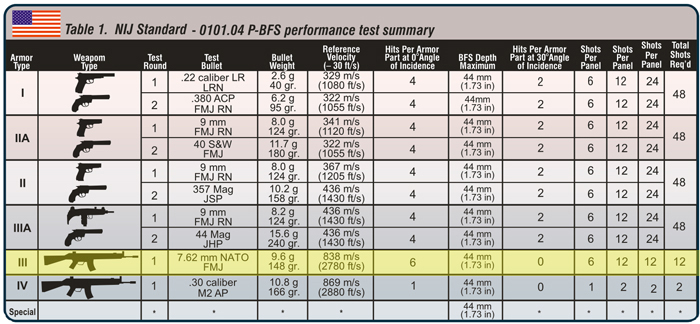

In a test, Dr Jawaid’s team fired a 7.62 mm caliber bullet into both the TEHBA and a Kevlar ballistic plate from 15 meters away, at a velocity of roughly 838 m/s. As for why these numbers are chosen, they appear to be the prerequisites for the US’s National Institute of Justice (NIJ) standard for Type III armor, which protects from rifles and everything from the preceeding types. Nah, diagram:

As you can see from the table, there are more things to the actual test than just the size and speed of the bullet, but all of them require that the backface signature (BFS Depth) not go deeper than 44 mm. From Dr Jawaid’s test, the resulting backface signature was 24.12 mm for the Kevlar plate, and a slightly higher 26.51 for TEHBA, both still way below NIJ’s requirements.

It seems that the TEHBA is almost as good as Kevlar when it comes to stopping bullets. However, to be fair we should mention that the NIJ’s 44 mm number had been mired with some controversy over the years, and that European, German, and British standards have a much stricter range of between 20-25 mm. Still, to get a pretty close result to Kevlar is quite impressive for something that we normally burn as trash, so one might wonder…

Who knows what other uses we can find from our untapped resources?

Previously, other than burning as trash, there doesn’t seem to be any proper use for coconut leaf sheaths. So to find such an unusual use for it is pretty impressive, even more so if you can see the amount of research that went behind it.

But body armor wasn’t the only thing that Dr Jawaid’s team had been working on. We can’t talk about those in detail for certain reasons, but the field of natural fibers and polymers may hold more possibilities than we think. There’s plenty of natural fibers in agricultural waste like empty oil palm fruit bunches and sugarcane waste, to name a few, and with them you can make some amazing things, like containers that can replace plastic, and even car parts.

In fact, Dr Jawaid told us that some cars now actually has more parts made of natural fibers than other materials. Heck, three years ago, a team of students from the Netherlands even built a working car almost entirely from materials derived from sugar beets and flax. Like the coconut bulletproof vest, we hear about them because they made it into the news, but other things remained unknown to the public.

“We’ve done a lot of research, but because the product did not come, we do not make the news, then people don’t know.” – Dr Mohamad Jawaid, to Cilisos.

Anyhow, knowing the possibilities of natural fibers, a bulletproof vest made from coconut leaf sheaths is probably not the craziest idea out there. With an open mind and some research, we can probably come up with more interesting applications for our less-looked at resources in the future.

- 708Shares

- Facebook678

- Twitter4

- LinkedIn6

- Email3

- WhatsApp17