Malaysia was the biggest natural rubber producer. Now, we’re depending on Thailand.

- 4.2KShares

- Facebook4.0K

- Twitter9

- LinkedIn11

- Email15

- WhatsApp75

If you still remember your Sejarah lessons, you’d know that Malaysia is known for its natural resources, one of them being natural rubber. Back in those days, it seemed like everyone, especially the US wanted a piece of Malaya’s rubber to the extent that the state had to import workers to work in estates.

The industry grew so much that Malaysia eventually became top makers of rubber gloves and even condoms. We’ve written how Malaysia became the top producer of condoms and you can read more here.

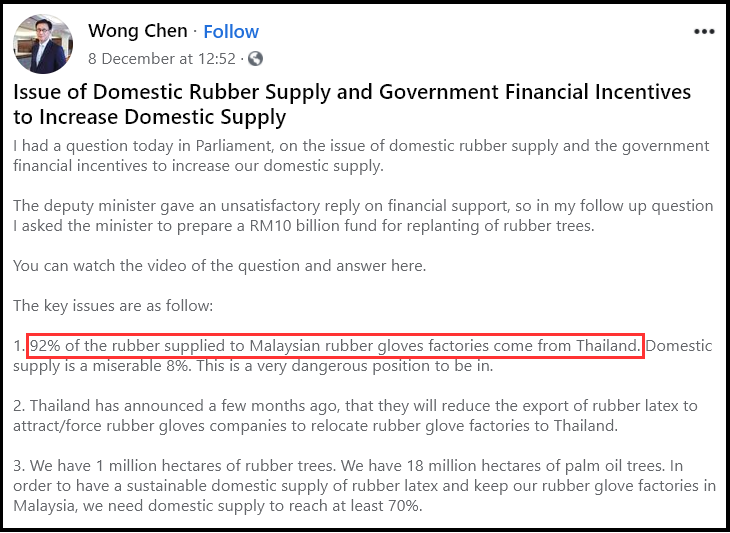

However, we recently found out that the local rubber industry is not as great as it used to be. Subang Jaya MP Wong Chen in his Facebook post recently pointed out that many local glove companies are only using 8% of domestically produced raw materials (read: latex).

Assuming you’ve read what was written in the screenshot above, you’d know that the remaining 92% of latex came from… Thailand(!). Wait, how did we go from being the greatest rubber producer in sejarah to this?

It all started when rubber companies quickly pulled out of Malaysia

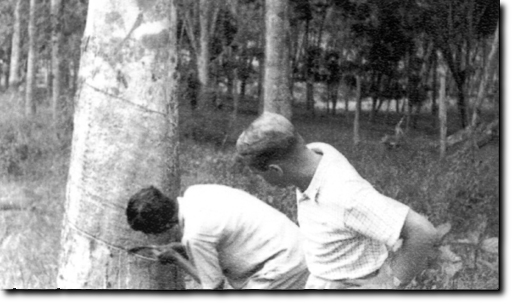

In the early 20th centuries, rubber wasn’t exactly a huge deal in Malaya because most people then were mining tins. But after the British colonialists brought in rubber in Malaya and promoted the potential of rubber commercialisation in the state, many companies were more attracted to the industry instead.

Back then, the demand for rubber, especially in the automotive industry (read: rubber tyres) spiked, causing the prices of natural rubber to increase as well. This caused a lot of smallholders, who normally own about 2 hectares of rubber plantation, to choose and stick with rubber over other plantations including rice.

In fact, this was how Malaya became the largest producer of natural rubber by the 1930s on top of the quality of the rubber produced thanks to the herring-bone tapping technique. But just as with some things in life, this only lasted for a while.

As it turns out, Malaysia’s glorious days in producing natural rubber only lasted till sometime in the 70s. Dr Sivakumaran Seenivasagam, R&D Executive Director of Greenyield Berhad, a local agricultural company, mentioned that, ever since, the number of rubber plantations have reduced over the years and Malaysia eventually became the fifth or sixth biggest producers of natural rubber after Thailand, Indonesia, Vietnam, India and China.

One particular reason for this was many large rubber companies pulled out of the rubber business and turned to palm oil instead. And the pull out game (it really is not what you think it is) is so strong that, at the time of writing, only 5% of natural rubber is locally produced by these companies.

“A significant reduction in natural rubber hectarage is due to large plantation companies exiting because of conversion to oil palm, which is more profitable per hectare and less labour-intensive (12ha per harvester for oil palm compared with 6ha per tapper based on tapping done once in three days), thus requiring much less labour and being less prone to disease.” – Dr Sivakumaran, as quoted by The Edge Markets.

The remaining 95% of natural rubber came from smallholders aka your typical rubber tappers. As of the time of writing, there are about 1.08 million hectares of rubber plantations in Malaysia, mostly owned by these smallholders.

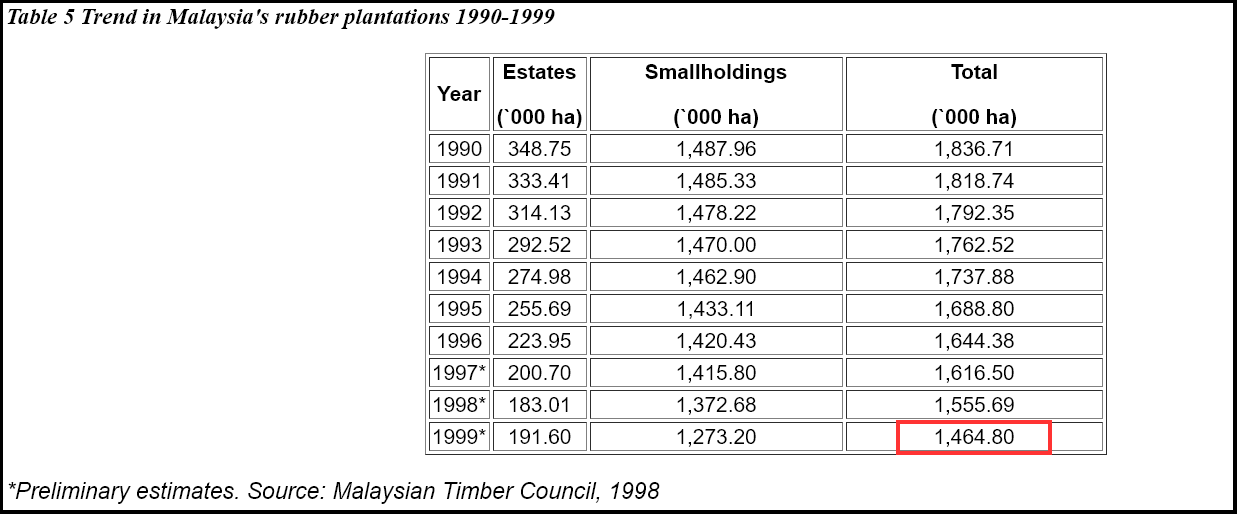

And that’s actually a pretty huge drop if we were to compare it with the 1.42 million hectares of rubber plantations Malaysia had in 1999.

But that’s just one tiny part of the problem.

Rubber tapping went from big moneymaker to side job

Although many rubber companies turned to palm oil for a better business, Malaysia still has a lot of rubber trees. And even with 1.08 million hectares of rubber plantations, the Malaysian Rubber Board (MRB) director general Datuk Dr Zairossani Mohd Nor claimed that rubber tappers can easily produce at least 1.2 million tonnes of natural rubber.

However, as of 2019, Malaysia only ended up with 640,000 tonnes of natural rubber. To make matters worse, more than half of rubber plantations in Malaysia were reportedly left untapped.

So, what went wrong?

For one, the job is no longer providing enough money for rubber tappers to feed their family. Imagine this: rubber tappers used to earn about RM5 to RM8 for every kilogram of rubber they sold in the late 90s. Rubber was sold at such a good price that, according to a Malaccan rubber tapper, Faridah Wahab, people would wanna steal their crops!

“By morning, people were already waiting in the nearby oil palm estate to steal the latex we’ve tapped. You go back to the plantation, and nothing looks out of place. But you go up to the cup and it’s empty already.” – Faridah, as quoted by CNA.

Nowadays, with what rubber tappers earn (between RM1.70 and RM2.10 per kg of rubber), we doubt anyone would wanna steal crops anymore. And, according to another rubber tapper, Ab Manap Minhat, these prices really depend on middlemen.

“Once a week, I’ll go around the different plots to tap, then collect the lumps around Friday morning, so by 10am on Friday, we can sell the cup rubber in buckets to the middleman buyer.” – Manap to CNA.

He mentioned that there are two types of middlemen – govt and private ones. Most of the time, rubber tappers could get a better deal when they sell their crops to govt middlemen as compared to private ones.

This explains why the Association of Bumiputera Rubber Entrepreneurs Malaysia (PUGBM) discovered that most of these guys roughly earn between RM900 and RM1,000 per month. Just as a comparison, the new poverty line in Malaysia is between RM980 and RM2,280.

Considering how low rubber tappers are earning from selling their crops, it makes sense why the job is slowly turning into a side job instead. Many of them like Manap had to do odd jobs such as weeding and small repair works to support their living.

And because most rubber tappers in Malaysia are warga emas, most of their children don’t see themselves filling the shoes of their parents. Well, some like Abdullahrus Mohd do, but they do it as a side job instead.

“The income from rubber is for holidays or extraordinary expenses. It’s hard to survive on rubber alone. We get only RM1.60 per kg from the rubber we sell. One kg of rice is how much?” – Abdullahrus, as quoted by The Edge Markets.

Although some of them are still tapping rubbers…

90% of Malaysian rubber can’t be used to make gloves (or condoms)

Rubber tappers in Malaysia normally produce two types of natural rubber – liquid latex and cup lumps.

Malaysia was known for its good quality latex back in those days and the country was producing an equal amount of latex and cup lumps. In fact, PUGBM’s president Kameruzaman Ab Rahman said the price of latex is higher than cup lumps.

But as years go by rubber tappers seem to prefer cup lumps over liquid latex. Why? Well, apparently it is more mafan and time consuming to deal with liquid latex.

“A tapper also needs to complete two rounds of tapping and collecting the latex, which takes a total of eight to 12 hours daily. On the other hand, cup lumps require only two to three hours of work, as the latex in the cup is collected on another day.”- Kameruzaman’s statement, as quoted by The Edge Markets.

Just to give you a clearer picture, rubber tappers can tap 1,000 trees to produce cup lumps as compared to 450 trees to produce latex. And producing more volume of natural rubber, whichever type they are, would only mean more kachings$s$.

At the time of writing, more than 90% of natural rubber produced in Malaysia are cup lumps. While this may mean decent money for rubber tappers, it also imposes a huge problem for the overall rubber industry – a mismatch between the type of rubber produced and what’s mainly used to make rubber products.

See, cup lumps are mostly used to make tyres but the tyre-making industry only makes up about 7% of the total amount of Malaysia’s rubber export. In comparison, 83% of Malaysia’s major rubber product exports are gloves and condoms.

Here’s the problem. As of 2019, the glove industry required 450,000 tonnes of latex but the country was only producing 8% (36,000 tonnes of latex) of what was needed by the industry.

So, when the local supply is not enough, companies have no other choice but to look for supply elsewhere.

Thailand is saving Malaysia. But not for long.

So, this is when Thailand comes into the picture as a hero… who’s probably dressed in latex… cos the country is saving us with its latex. #geddit? #notfunny #okbai #ihatecilisos

But it may not be too surprising that Malaysia is importing natural rubber from Thailand seeing how Thailand is the largest producer of natural rubber since the 70s anyways. However, it’s noteworthy that Malaysia generally imports 43% of natural rubber from Thailand.

The only problem here is how most, if not all, Malaysian glove companies are heavily relying on Thailand for latex. Remember how only 8% of domestically produced latex are used to make gloves? Well, the remaining 92% of latex used by these companies solely came from Thailand.

We’re not say that what these companies are doing is wrong tho but Wong Chen’s concern was Thailand’s plan to cut its exports soon. As it turns out, the Thailand govt rolled out a 20-year plan to reduce rubber plantations in its country and increase the value of exports by threefold in 2019.

And the aim of the plan was to make Thailand the main country in rubber planting, processing and exporting. This could mean that if Malaysia is not gonna produce more latex in the future, there is a high chance that glove companies are gonna close shop in Malaysia and move to Thailand. #GG

Over the years, the govt has been giving out various incentives to help rubber tappers like paying out an extra RM0.40 per kg of the rubber sold to govt middlemen besides a RM300 one-off cash aid. In fact, Deputy Minister of Plantation Industries and Commodities II Willie Mongin mentioned that the govt is planning to give more incentives to encourage youngsters to be involved in the industry.

But MRB’s Zairossani believe that the solution to this is by ensuring that a win-win system is produced. For a start, he urged glove companies to reduce the import of raw materials from other counties and start using the ones produced domestically.

“Glove makers can assist [smallholders] by committing a certain percentage of their raw materials to local supply. For example, if they are importing 90% of raw material from other countries, they should gradually reduce that to, say, 80%, so that we support our local market.” – Zairossani to The Edge Markets.

Although it might be costly for companies to do this, Zairossani believes that it might be possible, especially in the current pandemic. But we can’t tell if companies are actually considering this suggestion. If they do, we can only hope it would bring back Malaysia’s glorious days of producing rubber just like how it was portrayed in our Sejarah textbooks.

- 4.2KShares

- Facebook4.0K

- Twitter9

- LinkedIn11

- Email15

- WhatsApp75