Whoah. Malaysia invented a rubber product to protect buildings from earthquakes?

- 1.6KShares

- Facebook1.5K

- Twitter9

- LinkedIn1

- Email35

- WhatsApp59

A few days ago, the Minister of Plantation Industries and Commodities, Datuk Seri Mah Siew Keong had stated that Malaysia’s rubber industry is not a sunset industry, as some investors might have claimed. While the industry is still doing RM17.9 billion in 2015, it’s not quite what it was 30 years ago, when Malaysia was the largest exporter of rubber and the third largest producer of the world’s rubber.

However, their solution to the rubber downturn was what caught our eye. In the article, Minister of Plantation Industries and Commodities, Datuk Seri Mah Siew Keong outlined Malaysia’s ability to “produce high-value engineering rubber products used specially in the field of vibration and earthquake engineering.“

Whoah. So our rubber bands can be used to save buildings from earthquakes!?

When the 1995 Great Hanshin earthquake hit Kobe, Japan, it was touted as the costliest earthquake in world history, requiring somewhere north of USD400 billion to rebuild. Almost ALL their bridges were demolished by the quake, except for 5% of the bridges that were fitted with seismic rubber bearings. After rebuilding, now the number of bridges fitted with rubber bearings rose to 95%. The use of rubber bearings for bridges and buildings grew exponentially where other types of bearings had failed.

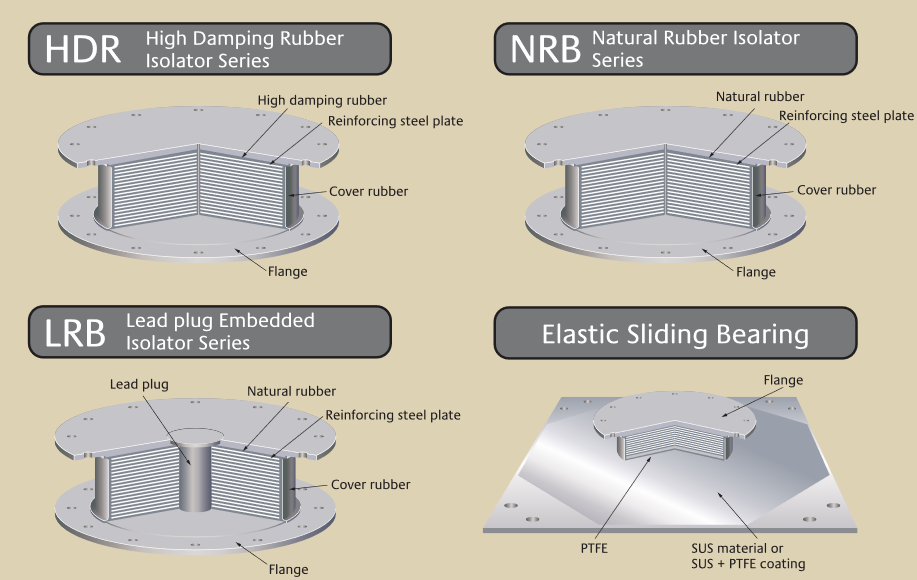

Rubber bearings work by keeping a building from direct contact with the ground and protecting it from earthquakes. Try to imagine your car with wheels made of concrete, and you’ll get the idea. If it sounds a little like troll physics to you, bear in mind that it actually works.

The solution is pretty much a stack of thin steel disks covered with rubber, kinda like how the wafer layers in a Kit-Kat is smothered with chocolate. This is so the steel and rubber can work together to support the heavy weight of a building at the same time, and last many decades (as good buildings should).

And here’s the thing… we invented this 60 years ago!

Sometime in 1955 in London, an engineering consultancy company called W. S. Atkins & Partners were tasked to stabilize a the soon-to-be constructed Pelham Bridge from the vibrations caused by vehicles moving on top of it. They thought of rubber bearings, and since rubber is kind of a new thing back then, they turned to the British Rubber Producers’ Research Association (BRPRA) to help them in designing bearings for bridges made of rubber (to be fair, the association was made up of alot of AngMohs, and a few Malayans). After Malaya achieved independence in 1957, the BRPRA moved its operations there (cos that’s where all the rubber was), and came to be owned by our Malaysian Rubber Board.

The bearings they developed were so good in absorbing vibration that they thought of using it to absorb vibrations from subway stations from disturbing the surface ground. So they decided on a block of flat housing called the Albany Court, which is situated right above a subway station. After the installation, the tenants of the flat can no longer feel the rumbling when a train enters or exits the station. It was a successful experiment, and soon they were vibration-proofing other buildings and hotels.

And then, in 1994, there was a massive 6.7 Richter scale Northridge earthquake in California. One of the few buildings that survived was the Foothills Communities Law & Justice Center, which was built 10 years prior with 98 rubber bearings… making it the first building to be protected from an earthquake by means of rubber bearings.

And Malaysia kept up the research of the tech after…

Shortly after the California earthquake, the Malaysian Rubber Research and Development Board worked with the United Nations Industrial Development Organization (UNIDO) on an experimental project to outfit buildings in less-developed, earthquake-prone countries with these seismic rubber bearings. The results from participating locations in China, Indonesia and Armenia showed that you can use these bearings to protect low-cost buildings in less-developed areas from earthquakes.

Then, towards the end of the 2000s Malaysia undertook the “Largest Base Isolation Project in the World“, quake-proofing the entire new town of Parand in Iran, a place with highly active seismic activities. The project sees the installation of HDNR bearings for some 10,000 units of homes, mosques, shopping centers and other buildings, with plans of doing the same thing to the kinda nearby-ish new town of Hashtgerd.

Since then, rubber bearings have been manufactured and installed in various countries susceptible to earthquakes, but a pretty huge installation may be closer than you think. It’s on Penang’s second bridge, Malaysia’s largest structure on rubber bearings. Completed in 2014, the Sultan Abdul Halim Muadzam Shah bridge contains over 2000 bearings to support it’s length from the vibrations from passing vehicles, the wind, and if there should ever be one, an earthquake.

But why did Malaysia feel the need to invent something it probably doesn’t need?

To be fair, it’s only started because W.S. Atkins & Partners asked us… but there is a good reason for that. At that time, Malaysia is well-known as a rubber producer, and the rubber we produced back then is of quite a high quality. In the 1930s half of the world’s rubber came from Malaysia. So it makes sense that at that time, Malaysia (or Malaya under the British rule) is considered the authority on rubber.

Plus, in his statement a few days back, the Minister of Plantation Industries and Commodities YB Datuk Seri Mah Siew Keong expressed the aim for the Malaysian rubber industry to move its focus towards rubber products in engineering. Earlier this year he had also voiced plans of rubberizing the roads in Malaysia as well, with stretches of road in Negeri Sembilan and Selangor already covered with rubberized asphalt.

Although the rubber industry has seen its ups and downs in the past half century or so, Malaysia had always remained one of the largest rubber producer and exporter, even though in more recent times we are falling a little behind. The rubber industry is, however, one of the 12 National Key Economic Area sectors, industries hoped to give Malaysia a high-income status. Therefore, diversifying our rubber products is a wise move in the effort to keep up with current times.

- 1.6KShares

- Facebook1.5K

- Twitter9

- LinkedIn1

- Email35

- WhatsApp59